|

|||||||

|

|

|||||||

|

|

Guardrail dragged down by posts

Posts with concrete footings

|

|

|||||

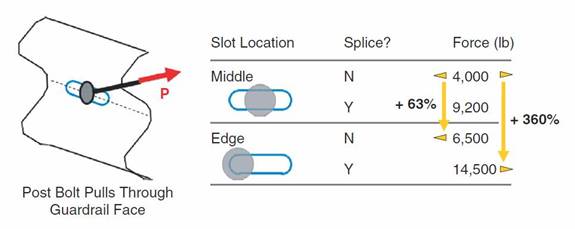

| Blocked out Last Century Road Guardrail Design The major failure of guardrail designed in the 1960’s and continues in 2017, as a generic system in the New Century is the variance in the load required to release the W-beam rail from the post. This release is dependant on the location of the post or (block out fitting) bolt in the rail slot and whether the connection is mid-span on the rail at the splice joint. The function of the C type post at impact is to twist and dredge in the soil loading the bolt to pull through the W-beam. As you can see the highest required load occurs when the bolt is at the end of the slot at a splice connection. The load effected to release the bolt at this location is 3.6 times greater than if the bolt is located central in the slot at a mid-span location. Hence the release load is highly variable and hence the performance of the system Is not dependable. Moreover the minimum release load at splice locations is excessive and physically problematic to the whole performance of the system for high-energy impacts. The installation of decades old generic guardrail often includes the addition of concrete footings to the C posts. Adding a concrete footing prevents the C post from twisting or moving thus preventing this action of the post from loading the W-beam fixing bolt for detachment of the rail. The result is that the posts at impact lie down dragging the W-beam rail with them and causing drive through, ramping or capsize. At speed deceleration forces are massive causing death or severe injuries to vehicle occupants. |

|||||||

|

|||||||

|

|||||||

|

|||||||